Angstrom Vision is a 3D sensor and quality inspection solutions provider for semiconductor, advanced display, optics, and microelectronics parts manufacturing industries.

We champion research and development to actualize what the optical 3D microscopy industry has long been pursuing: ultra-high resolution and accuracy, highly scalable depth of field in optical systems, high stability, and high-speed scanning. With unprecedented proprietary technologies, we commercialize novel 3D microscopes that are pivotal to advanced manufacturing industries.

Contact

➤ LOCATION

2-831 3rd Street West, North Vancouver, BC V7P 3K7

☎ CONTACT

info@angstromvision.com

(604) 230-9799

About Us

Angstrom Vision Inc. is a 3D vision and AI-based automatic inspection solutions provider for advanced manufacturing industries.

With the adoption of artificial intelligence technology, high-tech manufacturing industries are transforming rapidly. To empower manufacturers to eradicate defects and multiply production yields, our research and development of leading-edge 3D microscope technologies tackles antiquated in-line inspection issues.

Our unrivalled technology and products are distributed to 3D inspection equipment companies, strategic partners, and selected customers—especially those whose products enhance the human quality of life. We look forward to serving you with our commercialized technology and products.

Our Solutions

Angstrom Vision provides 3D/4D sensors and solutions for various industries. We pioneer digital holographic technologies that allow superior accuracy, unprecedented processing speed, and structural simplicity to miniaturized 3D devices.

View our solutions →

Products

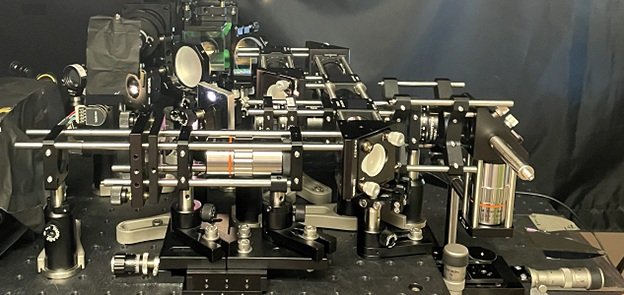

Angstrom Vision’s technology and products employ unmatched concepts in metrology, empowering manufacturers to measure targets instantly and precisely in 3D. With a broad field of view and clear and high lateral resolution, locating defects is easy. Manufacturers will be able to identify and eradicate the root cause of defects, developing a superior manufacturing process and becoming the first-to-market with premium products and prices.

Our 3D microscope can measure the thickness, depth, width, and shape of materials that have optically rough, opaque surfaces and specular surfaces (i.e., mirrors, polished metals, and chrome). It can also measure transparent materials and translucent films with particles located within the film layers.

We design and build 3D microscopes according to the industry required specifications in the following range, but not limited to:

Microscope type: reflection

Number of laser source: single to multiple

Height measurement range: up to 5mm

Height/vertical accuracy: down to 0.15nm

Vertical resolution: down to 0.1nm

Vertical repeatability: down to 0.01nm

Lateral resolution: <100nm; further down to tens of nanometres is feasible with DUV light sources, which relies on the wavelength, lens, and camera used

Field of view: from a few hundred micrometres to 50mm in X- and Y-axes depending on the lens and camera used and required lateral resolution

Types of lenses used: micro-objectives or telecentric

Camera: 1MP to 155MP

Measurement time for a single field of view with a 24MP camera: 30ms

Size of microscope head: ~550mm (H) x 450mm (W) x 100 mm (D) when an objective lens and camera are used; the height varies according to the type/number of optical elements and the number of wavelengths used

We understand the diversity of physical properties and features of material surfaces, surfaces of multi-featured parts in a single field of view, beam absorption ratio on material surfaces, and reflection index for transparent or translucent films. To find out if our 3D microscope is best suited for your needs, please contact us to discuss your specifications and requirements in detail.

Technologies

AI technology is leading the manufacturing industry to a new trend; but it is only with the convergence of physics, optics, quantum, and nanotechnology that AI would truly open new chapters. The development of ultra high-performance 3D microscopes that surpass the best existing microscopes can only be actualized when conducted in tandem with research in physics and optics.

We develop a new generation of 3D microscopes using fusion techniques that blend interferometry and digital holography techniques and introduce optics and geometry.

The Holographic Approach captures the phase and amplitude of optical fields, whereas conventional photographic imaging only captures the amplitude (i.e., intensity) of light.

Capturing the phase of a fast-oscillating optical field involves converting into intensity variations by mixing the optical field under study with a reference. Accordingly, holography requires a coherent light source (i.e., a good laser) or a low coherence light source (i.e., LED, white lights) and a beam-splitter to create object and reference waves. The object wave will illuminate the subject under study, while the reference wave will be mixed with the returned object wave at the image sensor. The intensity of object and reference field interference is measured in real-time by a digital camera, and phase and amplitude estimations of the object optical field are obtained by phase retrieval and holography image-processing algorithms.

The ability to capture phase opens doors to exciting possibilities like:

Digitally refocusing a captured image and identifying the best focus through offline digital processing after the hologram has been captured.

“Super-resolution” or compensating for optical aberrations of the imaging system to achieve the best theoretically possible resolution limit.

Ability to reconstruct the 3D shape of imaged objects.

These properties are used to create a digital holographic microscope that captures a 3D image instantly without the lengthy vertical scanning process, an inevitable part of confocal microscopy or white light interferometry. Moreover, these properties can be applied in developing other types of 3D devices used in biometrics, medical 3D imaging, and even camera industries.

In a sense, this holographic depth reconstruction can be seen as the ultimate fringe projection system, pushed to their limits. That is, the holographic fringes can have the finest structure possible. This would maximize image lateral resolution, positioning it much better than that of a traditional Moiré approach. Furthermore, the holographic fringes’ contrast would not be affected by the imperfections of the imaging lens. But this begs the question, “If digital optical holography is so beneficial, why is it not being used everywhere?”

In the following sections, we describe different barriers to applying the digital holographic microscope to practical tasks and present remedies of our own.

View our technologies →

Let's Chat.

Use the form below to contact us. Please include your industry and be as detailed as possible. To help us best serve your inquiry, we recommend that you first describe the issue you are having before telling us what you hope to achieve.

You may also email or call us to make an appointment.

We are always looking for new and exceptional talent to lead the company into new and uncharted fields of practice. For career opportunities, please email us your resume.